Tip 1: Opting for a coverall made from breathable fabric

Industrial leaders will recommend that you use type 5 and 6 coveralls. Type 5 and 6 coveralls use 3 types of fabrics. Refer to the table above for their general and key properties. The majority (if not all) of the brands on the market are based on any one of the fabrics. Or they can ben a variation or combination of it.

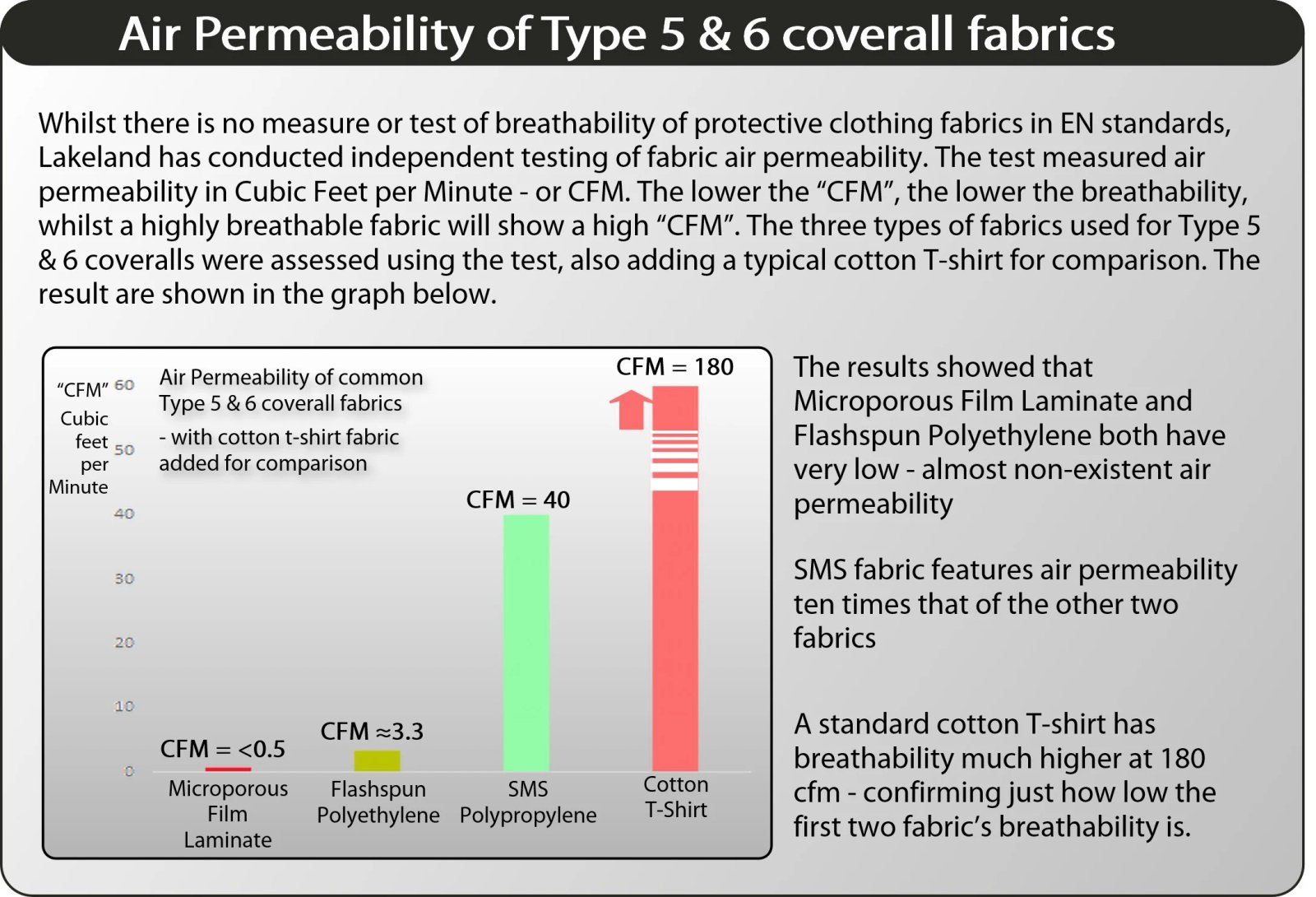

The most important point is that only one of those fabrics is entirely breathable: SMS or SMMS polypropylene. Flashpun Polyethylene and microporous film laminate have really low air permeability. Its permeability is so low that they have no breathability at all – for practical purposes.

Tip 2: Taping Up The Zip Flag

In all honesty, a high proportion of particles penetrate inside a suit through the zip. Either that or they go through the woven backing material of the zip or through its actual zipper teeth.

To be fair, it makes perfect sense. Zipper teeth gaps are possibly one of the biggest gaps in the garment’s construction. If the coverall is made of a non-breathable material, taping up the zip flap is one of the easiest ways to prevent airflow. You can also prevent particle penetration through the zip via this method too.

)

Tip 3: Choosing Coveralls with Sealed Seams

We have discussed about minimizing airflow and ingress through the fabric by opting for a non-breathable coveralls. Your next best choice is to prevent more dust contamination airflows is to pass through the seam holes in the stitched seams of your standard Type 5 coverall.

Your quick solution is to tape the seams of your PPE coveralls in the same method of the zip flap. In all honesty, this is realistically clumsy and time-consuming. So, if you can avoid this method, then it’s good.

Fortunately for many of you reading this, manufacturers will usually provide the option where they do this for you. They will stitch the seams, and then tape it over to seal up all the holes. They have basically just prevented airflows and dust particles from passing through.

These coveralls tend to have double-side tapes on the zip flap. It helps and enables sealing of the coverall without the use of more tape.

Tip 4: Tape Up Coverall and Other PPE Items’ Connections

Taping up your non-breathable coveralls through its zips can only do that much. To be honest, there can be little to no penetration through fabrics, zips, or seams. Therefore, you must ensure there are 0 gaps penetrated through your coveralls.

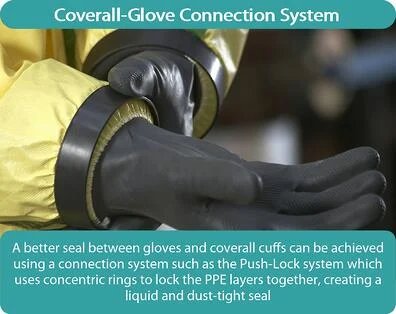

To put this in simple words, there must be no gaps (at all) between your coverall and other PPE gears that you are wearing. Keep the gaps between the cuffs, ankles, elasticated face close. The only method to tackle this is to tape up these gaps the same way you will with the zip flap.

Tip 5: Choosing a Gas-Tight Suit

Dust is a light particle that moves with the help of airflow. Air is gas. In the more extreme cases the best choice for you to maximise dust protection is choosing a fully gas-tight suit. This way, the user will not be exposed to any possible inward dust particle leakage.

The above 5 tips are to improve dust protection for the average PPE coverall wearer from hazardous concentrated dust. This is especially important when exposed to high hazard and high concentration applications. You just have to ensure to know the following to maximise protection of your workforce:

We hope that these tips are able to help and guide you in some ways when it comes to PPE coveralls. If you are looking for PPE equipment to meet your needs, do not hesitate to contact us. We have just the right PPE supplies you are looking for.

+6085 - 416 320 / 433 101

+6085-433801